The importance of maintenance for plant efficiency

Anyone involved in the industrial sector knows that the routine maintenance of any machinery or plant is a key element for production efficiency and management cost limitation. For this reason, the care that each manager devotes to the maintenance of the machines and systems of the company must always be impeccable. That is why it is necessary to entrust this activity to professional technicians in whom one can place the utmost trust.

Efficient systems reduce energy costs and avoid forced shutdowns

At Art-Eco, we have also decided to focus on the quality of our specialist technicians, to ensure that all our customers can benefit under all circumstances from this fundamental activity. Among the values that we follow in doing business are the centrality of people and the environment, and we know that the way to ensure both is full commitment during our work: from design to maintenance.

On the other hand, in order to ensure a healthy microclimate in the workplace, we must offer companies efficient cooling and heating solutions, but also guarantee a maintenance service that ensures that these systems are always in the best possible condition. For this reason, we have selected a team of specialist technicians who follow the customer at all times and particularly the installation of our products and after-sales maintenance.

Are you interested in more information

on evaporative cooling

Industrial cooler maintenance

Industrial cooling systems require careful checks, especially before winter shutdown and preparation for use in the warm season. This is because although the operating principle of coolers is simple and environmentally friendly, attention must be paid to a few details that may be crucial to ensure the long-term performance of these machines.

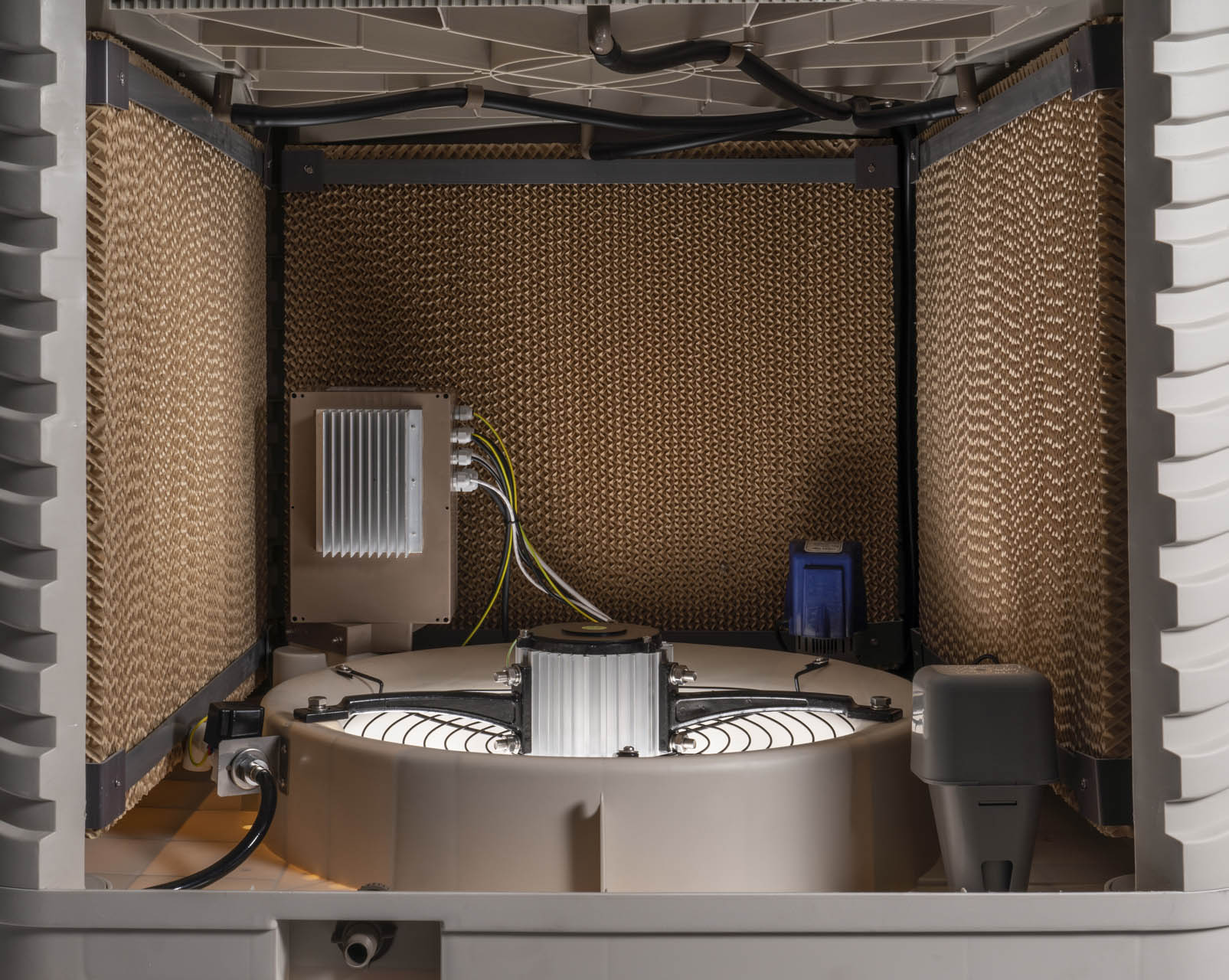

Fixed evaporative adiabatic coolers, such as those that Art-Eco recommends for companies wishing to ensure a healthy and pleasant microclimate in an industrial shed or warehouse, are rather simple but super-efficient machines. They basically consist of a fan that pushes the hot air from the outside through panels, called evaporator packs or pads, over which cool water flows. In this way, the air transfers heat to the water and becomes cooler, before entering the area being conditioned and pushing out the warmer, carbon dioxide-rich air. The arrival of the cooler air in the environment helps to simultaneously lower the temperature and renew the air, with beneficial effects confirmed by numerous studies, especially in recent periods. During this process, part of the water evaporates as it passes over the evaporator packs, while the remainder (about 20 per cent) is collected in a tank and thanks to a hydraulic pump is recirculated in the system together with fresh water.

As already indicated, our specialist technicians regularly check all of our customers’ systems and industrial coolers. If no faults are recorded during the summer period, two routine maintenance interventions take place, one before winter shutdown and again in preparation before restarting them in preparation with the warm season. During these interventions, all machine parts will be carefully inspected, with special attention to the evaporator packs, which are the most prone to wear and tear and which, if damaged, can considerably reduce the functionality of the cooler. Of course, in addition to these two annual routine maintenance operations, Art Eco technicians are always available for extraordinary maintenance at any time at the request of the customer.

Our technicians will also carefully check that no mould or bacteria colonies have developed in the water tank and on the evaporator packs themselves. In fact, during our routine maintenance activities we use specific products to avoid these problems – such as our ECOOL-IGE ioniser -, and all the components are always thoroughly dried before being put to rest, precisely to avoid moisture stagnation. We always prefer to carry out an extra check to guarantee the highest quality.

The two key moments are the preparation for winter shutdown and the checks before reactivating the systems for the warm season

Art-Eco’s specialist technicians

This maintenance work on fixed cooling systems requires both meticulous care but also a very thorough knowledge of the machines on which work is being carried out. Although, as we have said, Art-Eco fixed adiabatic coolers feature a simple and well-designed structure, it is nevertheless better that the work is carried out by specialist technicians who have gained significant experience as regards to the issues typical of this type of machine.

For this reason, Art-Eco takes care of following its customers at every stage: from the analysis of the current situation and the thermal problems of the environment to be cooled to the detailed design of the system, from the installation and testing of the machines to the consultancy service and routine and extraordinary maintenance.

At each of these steps, you can be sure that you will be followed by the same specialist technicians, who will always be able to guarantee maximum energy efficiency to cool your working environment, reducing the running costs of your company and helping you to be a green company, more and more attentive to environmental sustainability.